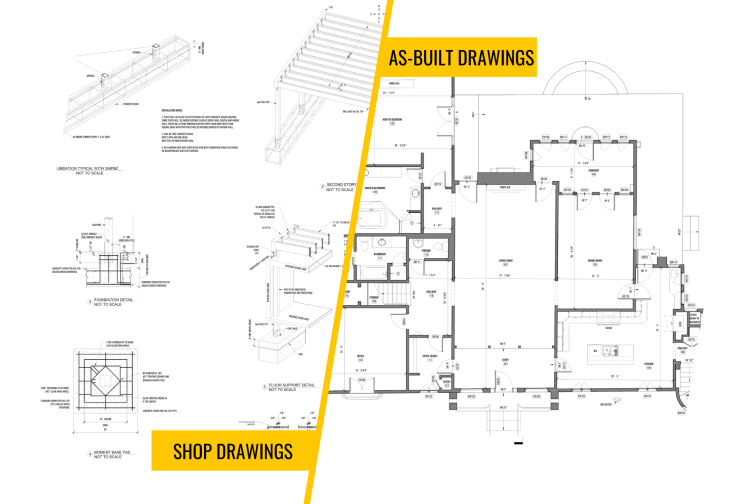

Difference between Shop Drawings and As-Built Drawings

Are you curious about the key differences between shop drawings and as-built drawings? Shortly, shop drawings serve as detailed representations created by contractors or fabricators to guide the fabrication and installation process. On the other hand, as-built drawings provide an accurate record of the final construction, documenting any changes made during the building process. By understanding the differences between shop drawings and as-built drawings, you'll gain valuable insights into their respective roles in ensuring project accuracy and success.

Defining Shop Drawings

Shop drawings are detailed, often highly specialized, and customized drawings or diagrams created by contractors, manufacturers, or fabricators to illustrate the specific details and dimensions of a particular component or item to be used in construction or manufacturing projects. These drawings provide a more in-depth view of the design and serve as a guide for the production or installation process. Shop drawings are typically created after the approval of the general design or construction drawings.

Shop drawings typically include detailed information about measurements, materials, finishes, and other specifications related to the particular component being represented. For example, if we consider a steel beam, shop drawings would provide information about its size, shape, connections, and any additional details necessary for fabrication and installation.

These drawings are created based on the original design plans provided by architects and engineers. They serve as a bridge between the design phase and actual construction by providing precise instructions to builders and installers.

Key features of Shop Drawings include:

Detail Views: Detail views focus on specific areas or components of the project, providing enlarged and detailed illustrations of critical details. This helps fabricators and installers understand how different parts come together.

Dimensions: Accurate dimensions are crucial in shop drawings to ensure that the fabricated components fit precisely within the overall structure. Dimensions include length, width, height, thickness, and any other relevant measurements.

Material Specifications: Shop drawings specify the materials to be used in the fabrication of each component. This includes details such as material type, grade, thickness, finish, and any other relevant characteristics.

Sections and Elevations: Sections and elevations provide vertical and horizontal views of specific components or areas, showing how they relate to the overall structure. This helps in visualizing how different elements interact.

Assembly Details: Assembly details illustrate how various components come together to form larger assemblies. This includes details about connections, fasteners, welding, or any other methods used to join the parts.

Welding Symbols: If welding is involved in the fabrication process, shop drawings may include welding symbols to indicate the type of weld, size, and location.

Bills of Materials (BOM): BOMs list all the materials required for the fabrication of each component. This includes quantities, descriptions, and part numbers.

Finishing Details: If applicable, finishing details specify the surface treatment or coating to be applied to the components. This may include paint colors, textures, or other finishing requirements.

Cutting and Shaping Instructions: Shop drawings may include specific instructions for cutting and shaping raw materials, such as steel or wood, to achieve the desired shapes and sizes.

Annotations and Markings: Annotations provide additional information or clarification about specific details on the drawings. Markings, such as reference numbers, are used to correlate different views and details.

Benefits of Shop Drawings

Enhanced communication and visualization

Minimized errors and rework

Streamlined fabrication process

Efficient coordination among trades

Simplified ordering and scheduling

Defining As-Built Drawings

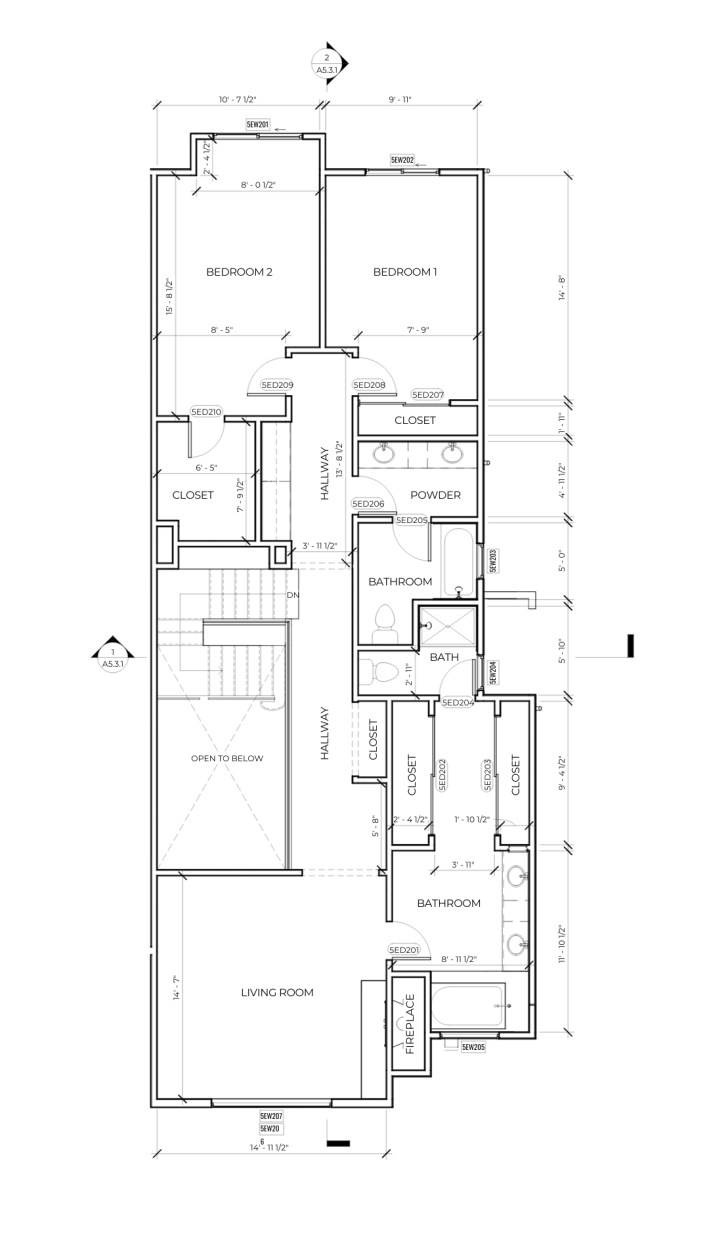

As-Built Drawings are an important document in the construction industry, providing a detailed representation of a building or project as it actually exists. These drawings serve as a record of the final state of the construction, including any modifications or changes made during the building process or after initial construction.

As-Built Drawings represent the actual measurements, dimensions, and elements of a completed structure. They are created after construction is finished and reflect any variations from the original plans. These drawings include information about the placement of walls, doors, windows, electrical systems, plumbing fixtures, and other components that make up the building.They’re also very important when planning remodeling, but there’s no as-builts on file for the building.

As-builts key features includes

The components will depend on the specific project and its requirements. However, there are some common elements that can be found in most Existing Conditions Drawings.

Building Layout: The layout plan shows the overall arrangement of rooms and spaces within the building.

Dimensions: Accurate measurements are provided to ensure precise representation of each element or space. The itemized schedules can be generated for a report of the existing amount of windows, their sizes, types of opening, etc.

Utilities: Details about electrical systems, meters and equipment, HVAC (heating, ventilation, and air conditioning) systems, and other utilities are usually included too. You may also request detailed information about the location of electrical fixtures, lighting fixtures, and even circuits.

Structural Elements: The drawings depict structural components such as beams, columns, foundations, wall framing layout, floor structure, attic and foundation plans.

Finishes: Information about flooring materials, wall finishes (stucco or siding), ceiling types, etc., is included.

Benefits of As-Built Drawings

Accuracy in documentation

Compliance with regulations

Facilitating future modifications

Maintenance and facility management

Key Differences Between Shop and As-Built Drawings

| Shop Drawings | As-Built Drawings | |

|---|---|---|

| Timing | Created during the pre-construction or construction or planning phase before the actual fabrication or installation of components begins. They are based on the design or construction drawings and provide detailed information for manufacturers and contractors to produce and install specific elements accurately. It may take multiple circles before the shop drawings meet all expectations and regulations. | Created after the construction is complete. They reflect the actual conditions and dimensions of the constructed elements, capturing any changes or deviations from the original design that occurred during the construction process. Typically they are done within three weeks of record or scanning. |

| Content | Contain detailed information about the materials, dimensions, fabrication methods, and assembly details of specific components. They are highly detailed and are used as a guide for the fabrication and installation process. | Document the actual dimensions, locations, and configurations of elements as they were constructed. They incorporate any modifications, changes, or additions made during construction that may differ from the originally planned design. |

| Intended Use | The primary purpose of shop drawings is to guide the fabrication and installation of components accurately. They are submitted for approval to Building Departments before the manufacturing or construction process begins to ensure alignment with the design intent and project specifications. | As-built drawings serve as a record of the final, constructed conditions of a project. They are used for facility management, maintenance, and future renovations, allowing for informed decision-making during the building's lifecycle. |

| Approval Process | Before fabrication or installation begins, shop drawings are typically submitted to the local Building Department for approval. Approval ensures that the proposed components meet minimal requirements and specifications for the specific area. | Used as a start point for renovation approvals, to show the pre-reconstruction conditions of the building and surrounding to ensure that all additions will comply with the codes and general design. Also used for Demolition permits. |

| Scope of Information | Focus on specific components, materials, and fabrication details, providing a detailed view of how individual elements come together. May not include the entire structure, but only a certain area of work. | Capture the overall built environment, including the final dimensions, locations, and configurations of all elements as they exist at the moment. |

In conclusion, shop drawings and as-built drawings serve distinct purposes in the construction industry. Understanding the key differences between shop drawings and as-built drawings is essential for all stakeholders involved in construction projects. By recognizing their unique functions and benefits, architects, engineers, contractors, and homeowners can better appreciate their significance throughout the entire construction process.